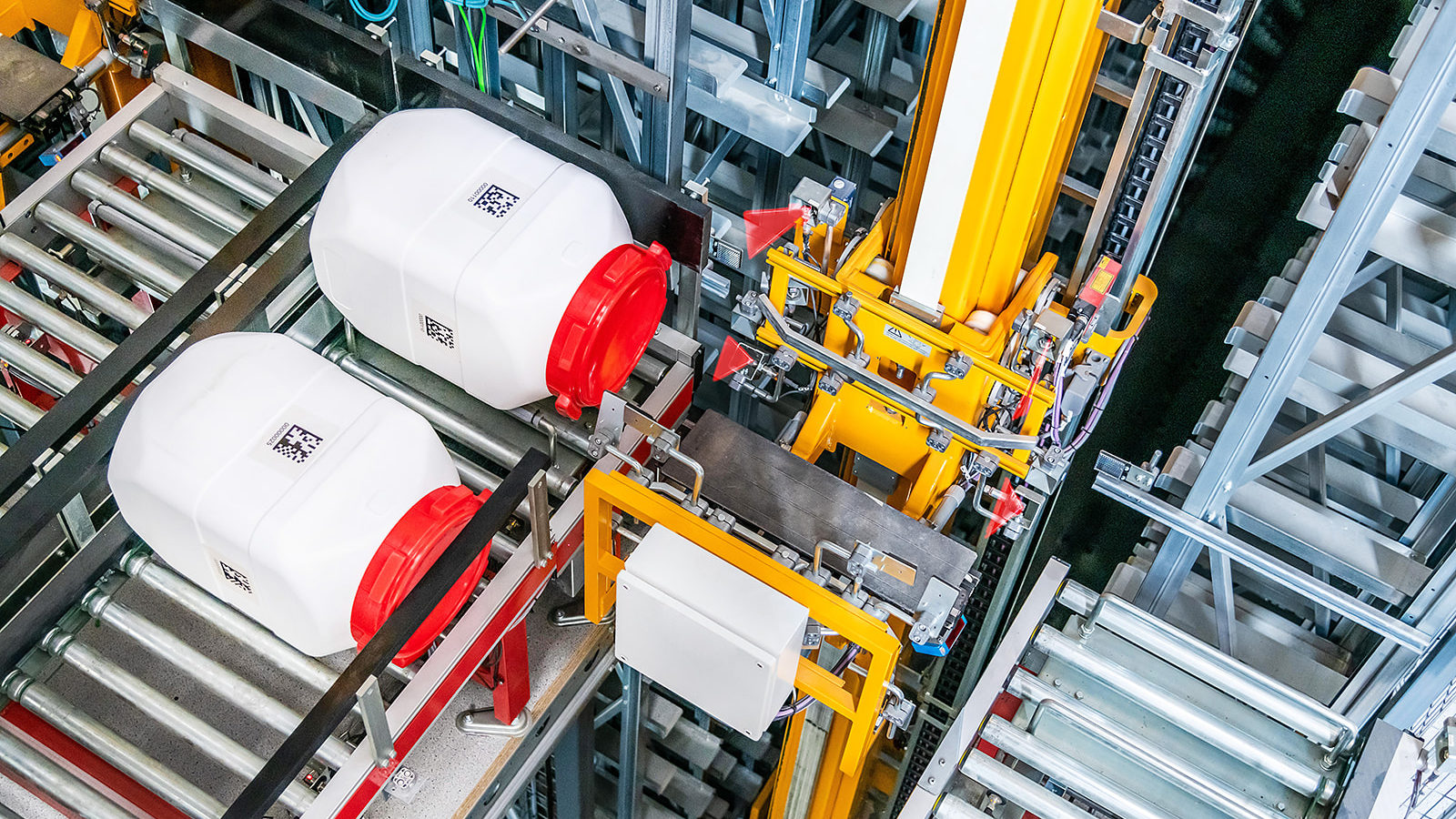

AS/RS module

The reliable control of automated systems.

The reliable control of automated systems.

Advice for your warehouse issue?

The AS/RS (automatic storage and retrieval system) module takes care of the control of fully automatic storage and retrieval systems. This concerns the control of, for example, mini-loads, high bay cranes and/ or robots. This module of our Arrow WMS, chooses the optimal location to have goods available at the right place, at the right time. So frequently sold items are available at quickly accesible locations and combination orders from the same rack are put in the right place by robots.

By controlling a collective collaboration of various fully automated inbound and outbound systems via our WMS, a piece of warehouse auomation is realized. The role of the AS/RS module within the Arrow WMS provides control over the location of the goods resulting in:

Curious how the software module for a AS/RS system can optimize your warehouse?

The AS/RS module offers the WMS the possibility to control various fully automated inbound and outbound systems. Think of mini-loads, stackercranes or robots. In the case of robots, for example, a signal can be sent to a robot. This tells the robot that it must pick up a certain rack and bring it to a picking zone. The system is clever in that if a pallet must be ready at a certain time, the robot will make sure a little before that the right boxes are ready and brought to the picking zones. In this way, the pallet in question can be filled for shipping. The module let robots to work together within the warehouse.

Customers about Costo

Clients

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.