WCS

The reliable control of automated processes.

The reliable control of automated processes.

Advice for your automation issue?

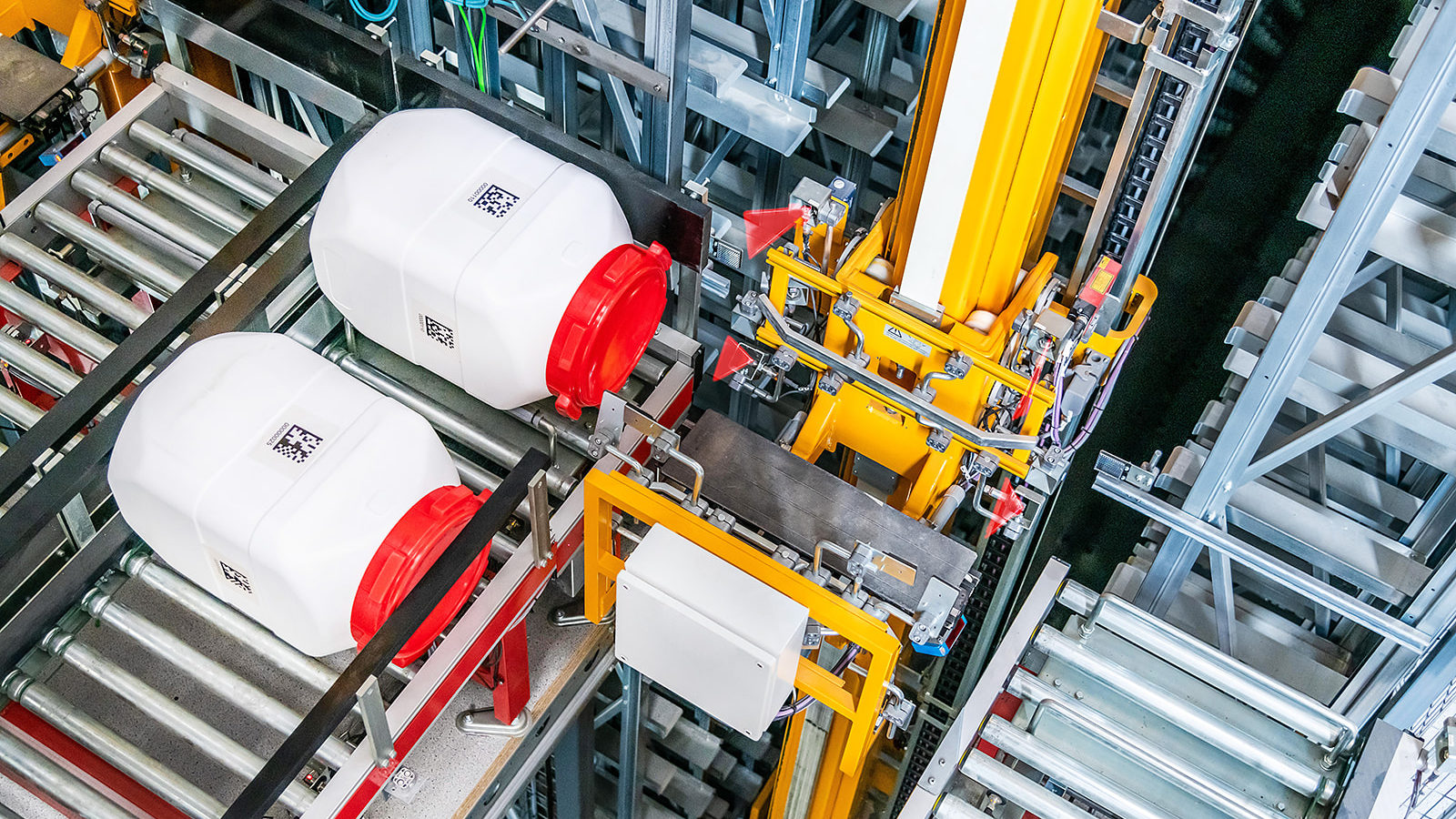

An efficient control of mechanized and automated material handling system is important for a flawless process. The warehouse control system (WCS) takes care of this control and the monitoring of the various (sub) processes. Within material handling warehouses and associated systems, the WCS allows various complex insertion situations to run smoothly.

Because all (sub) processes run smoothly into each other, you work wih a process that is optimized for your warehouse. The WCS can be easily adapted to the specific warehouse automation needs. A WCS offers important advantages such as:

Curious how a WCS can optimize your warehouse?

A warehouse control system (WCS) is a software application for managing and controlling material handling systems. It’s the link between the warehouse management system (WMS) and intralogistics systems. The WCS is responsible for the efficient and correct operation of conveyors, shuttles, pick-to-ligh systems, AGV’s and AS/S systems, among others. Based on predetermined data and real-time data, the WCS controls the various systems. The software also continiously monitors performance, so that quick and appropriate action can be taken if necessary. This ensures optimum utilization of the systems and maximum efficiency.

Customers about Costo

Clients

Advice

Do you want advice for automating your warehouse? Please feel free to contact us. Our experienced team will be glad to help you!

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.